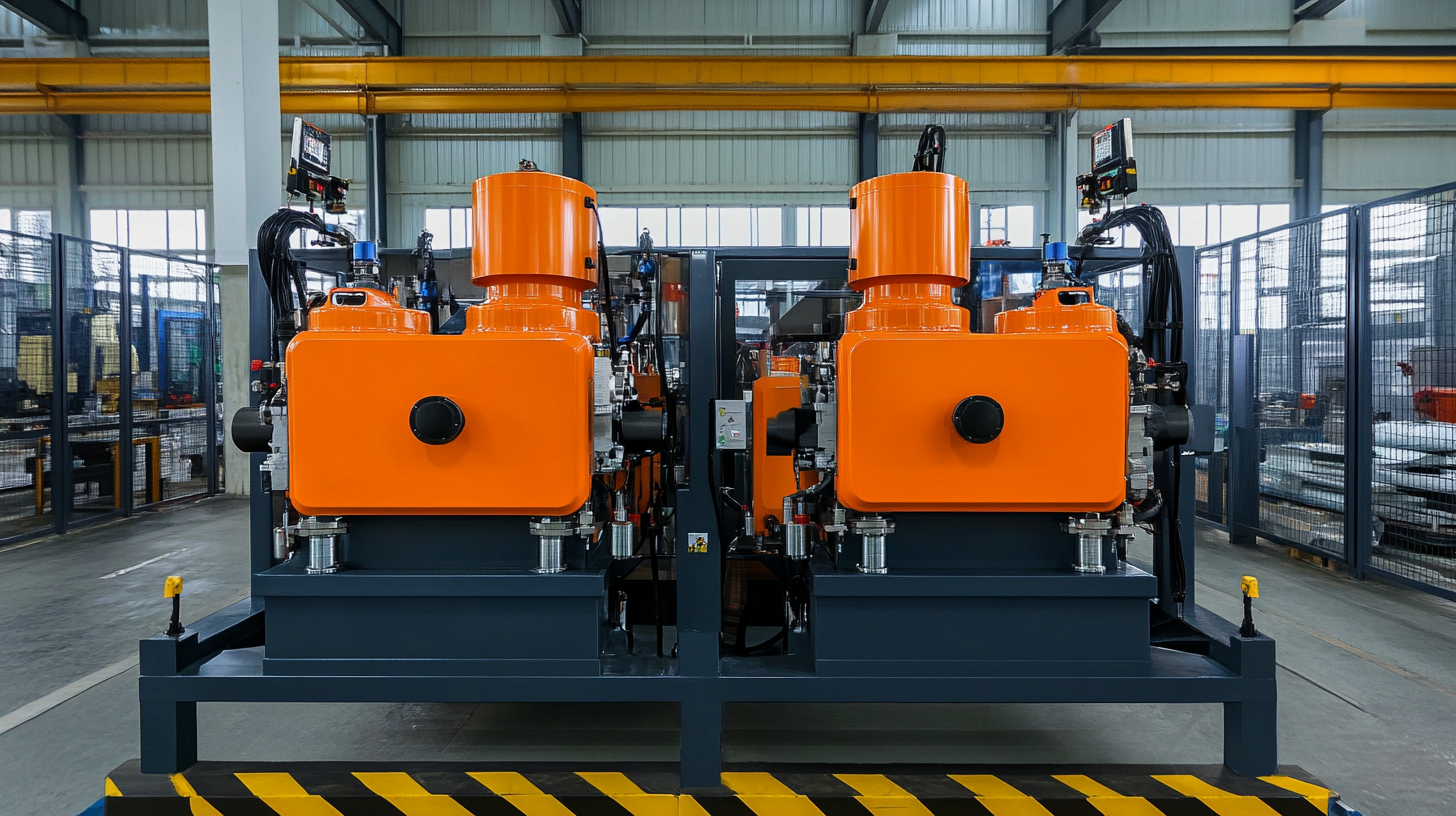

In today's rapidly evolving manufacturing landscape, the search for enhanced efficiency and productivity has never been more crucial. The emergence of innovative technologies plays a pivotal role in reshaping production processes across various industries. Among these advancements, the Double Bottle Suction Machine stands out as a remarkable solution designed to streamline operations and improve output quality. Originating from China, this cutting-edge equipment is transforming how businesses handle bottle filling and packaging tasks. By significantly reducing operational time and increasing throughput, the Double Bottle Suction Machine is not only optimizing production efficiency but also reinforcing global competitiveness. As industries worldwide seek to elevate their operational standards, understanding the capabilities and benefits of this revolutionary machine becomes essential for staying ahead in a crowded marketplace.

The manufacturing landscape is undergoing a transformation with the advent of double bottle suction machines, particularly those emerging from China. These innovative devices are proving to be game-changers, streamlining production processes and significantly boosting efficiency across various industries. By utilizing dual suction capabilities, these machines can handle more volume in less time, allowing manufacturers to meet growing global demands without compromising quality.

When integrating double bottle suction machines into your production line, consider these tips for optimal performance. First, ensure regular maintenance to keep the machines running smoothly; this not only extends their lifespan but also minimizes downtime. Second, invest in employee training to familiarize your workforce with the new technology, maximizing its benefits. Lastly, continually monitor production data to identify areas for improvement, allowing you to adapt and enhance your manufacturing strategy effectively.

The rise of double bottle suction machines is not merely about efficiency; it represents a shift towards smarter manufacturing practices. As companies increasingly adopt these technologies, they are finding new ways to innovate and improve their production models, ultimately leading to a more competitive edge in the global market.

The innovative double bottle suction machines from China stand out as a transformative solution in the global production landscape, particularly within the thermos bottle market. With the market projected to grow significantly, from USD 5.60 billion in 2025 to an impressive USD 8.08 billion, these machines play a pivotal role in enhancing production efficiency. Their advanced technology minimizes operational downtime and maximizes output, ensuring manufacturers can meet rising consumer demand effectively.

Key features of these machines include high suction power, enabling the efficient handling of various bottle shapes and sizes. They are designed with user-friendly interfaces, making them accessible for operators, regardless of their technical expertise. Additionally, energy efficiency is a hallmark of these machines, allowing companies to reduce operational costs while maintaining high productivity levels. As global manufacturers continue to compete in the thermos bottle industry, the adoption of such innovative machinery will be crucial in sustaining growth and improving overall production practices.

Innovative double bottle suction machines from China are revolutionizing production lines across various industries. These advanced machines not only enhance efficiency but also significantly contribute to sustainability standards. By optimizing the suction process, they minimize energy consumption and waste production, aligning with the global push for eco-friendly manufacturing practices. This innovation helps companies reduce their carbon footprint while maintaining high output levels, demonstrating that efficiency and sustainability can coexist harmoniously.

Tip 1: When considering the integration of double bottle suction machines, evaluate your production workflow to identify specific areas where efficiency can be improved. Implementing these machines can streamline processes and contribute to long-term cost savings.

Moreover, the double bottle suction technology is designed to adapt to various production environments, making it suitable for both large-scale manufacturers and smaller businesses. This adaptability not only enhances overall productivity but also allows companies to meet diverse client demands promptly.

Tip 2: Emphasize staff training on the use of new machinery to maximize its potential. Well-trained employees can ensure that the machines operate at peak efficiency, further contributing to sustainability goals and production output.

This pie chart illustrates the various impacts of innovative double bottle suction machines on global production efficiency, highlighting their contributions to increased efficiency, waste reduction, enhanced sustainability, and higher production capacity.

The innovative double bottle suction machines emerging from China have made significant strides in enhancing global production efficiency across various industries. Case studies demonstrate how these machines have been successfully implemented in sectors such as food and beverage, pharmaceuticals, and packaging. For instance, a prominent beverage company reported a 30% increase in production speed by integrating these machines into their bottling line, allowing for higher output without compromising quality.

In the pharmaceutical industry, a leading manufacturer experienced a drastic reduction in product losses during filling processes. By utilizing double bottle suction technology, they minimized spillage and increased the accuracy of dosage delivery. This efficiency not only leads to cost savings but also enhances product reliability, ultimately benefiting consumers.

Tips for those considering adopting double bottle suction machines include conducting thorough market research to identify the right model for specific production needs. Additionally, ensure proper training for staff to maximize the technology's potential, which can further streamline operations and improve overall productivity. Investing in regular maintenance will also extend the lifespan of these machines, ensuring sustained performance in the long run.

The advent of double bottle suction technology is poised to revolutionize the manufacturing landscape. As industries worldwide strive for enhanced efficiency and reduced waste, this innovative solution provides a means to optimize operations significantly. By utilizing two suction bottles, these machines can simultaneously handle multiple materials or products, increasing productivity while minimizing resource consumption. This dual-action approach not only accelerates production cycles but also streamlines the logistics involved in material handling, making it an essential addition to modern factories.

Looking to the future, we can anticipate that double bottle suction technology will continue to drive advancements in manufacturing processes. As manufacturers seek to implement more automated systems, these machines will become integral in achieving greater precision and speed. Moreover, the emphasis on sustainability will encourage the adoption of such technologies, as businesses look to decrease their environmental footprint while maximizing output. Ultimately, this innovative approach will reshape manufacturing methodologies, facilitating a shift toward smarter, more sustainable production practices across various industries.