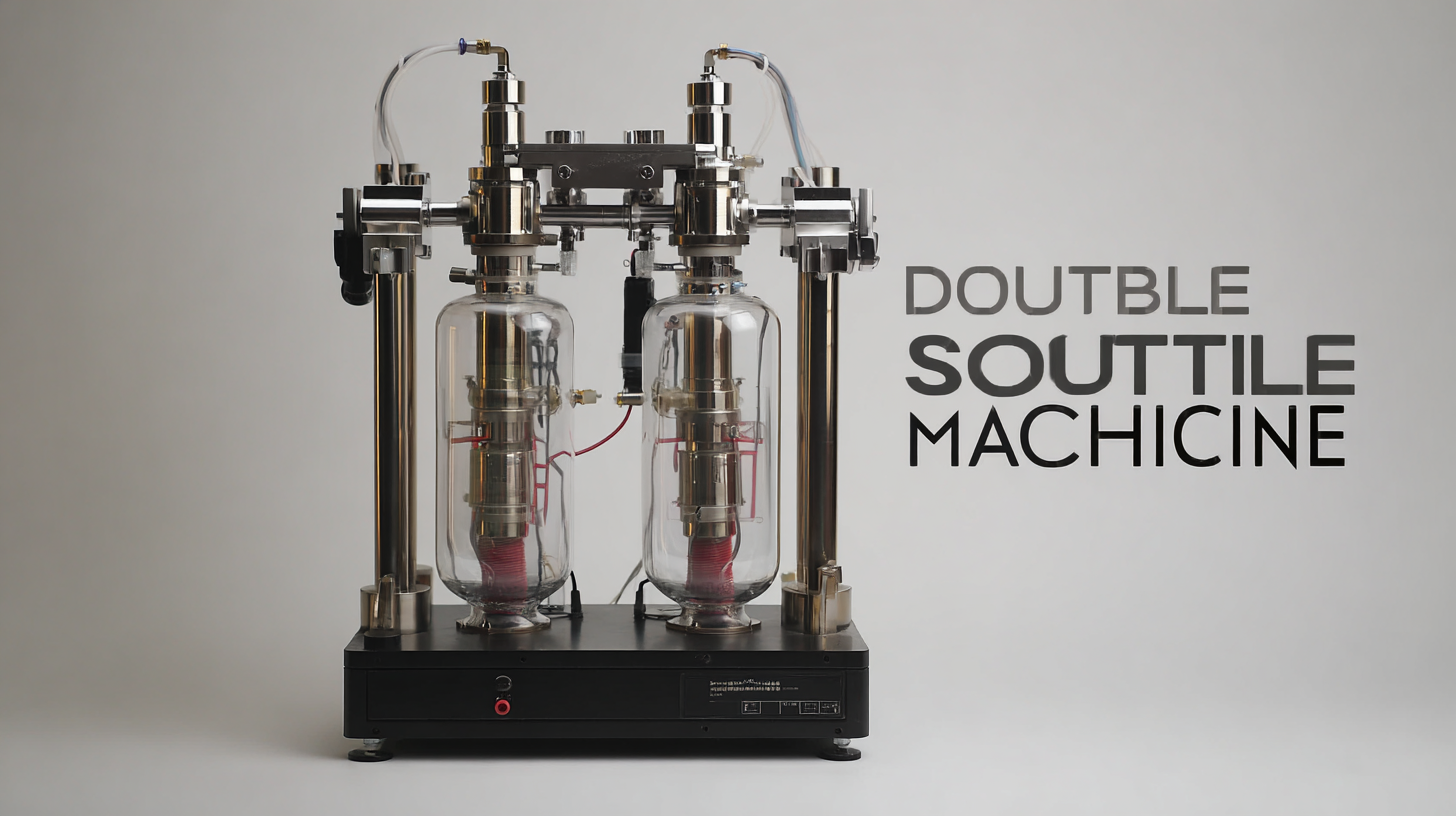

In the rapidly evolving landscape of liquid handling technology, the demand for efficient and innovative solutions has never been greater. The global liquid handling systems market is projected to grow substantially, reaching an estimated value of $6.6 billion by 2026, according to a recent market research report. Among the standout advancements in this field is the Double Bottle Suction Machine, a device that enhances the precision and efficiency of liquid transfer processes. This machine not only minimizes cross-contamination risks but also streamlines workflows in various industries, from pharmaceuticals to laboratories. With its dual bottle system, the Double Bottle Suction Machine significantly reduces the time and effort required for liquid handling tasks, making it an invaluable asset for professionals seeking to optimize their operations. This ultimate guide will delve into the features, benefits, and applications of the Double Bottle Suction Machine, highlighting why it represents a game-changing innovation in liquid handling technology.

The double bottle suction machine market is being propelled by innovative technologies that enhance liquid handling efficiency across various industries. With a projected market size expected to reach USD 8.08 billion by 2028, the advancements in suction technology are transforming standard practices. Manufacturers are increasingly focusing on the integration of smart features and automation in these machines to meet the growing demand for precision and reliability.

Tips for maximizing the efficiency of your double bottle suction machine include regularly maintaining the equipment to prevent contamination and ensure optimal performance. Additionally, training staff on best practices for liquid handling can reduce waste and enhance safety in operation.

As demonstrated by recent awards in the baby care industry, innovative solutions are making significant impacts. For instance, a notable portable breast pump product was recognized for its user-friendly design and convenience. Such recognition highlights the importance of innovation in creating solutions that address specific user needs while driving market growth in the double bottle suction sector.

This chart illustrates the market share of different innovative technologies driving the double bottle suction machine market in 2023. The data represent the percentage of market penetration by each technology.

In today's fast-paced industrial landscape, compliance with key industry standards and regulations is crucial for ensuring the safety and efficiency of liquid handling equipment. Understanding these guidelines helps businesses choose the right tools, such as double bottle suction machines, which are designed to handle liquids safely and effectively. Key regulations often include OSHA, EPA, and ISO standards that emphasize the need for safety, environmental protection, and quality assurance in handling hazardous materials.

When dealing with liquid handling equipment, consider implementing these essential tips:

First, always assess the compatibility of your suction machine with the liquids being processed. This not only extends the life of the equipment but also minimizes contamination risks.

Second, regular maintenance and inspections are vital. Keeping machinery in optimal condition ensures compliance with safety regulations and boosts operational efficiency.

Lastly, training staff on proper usage and best practices for liquid handling can significantly reduce accidents and enhance workplace safety.

By adhering to these standards and tips, companies can ensure their liquid handling solutions not only meet regulatory requirements but also contribute to a safer and more efficient working environment.

In the realm of laboratory and industrial applications, efficient liquid handling is paramount. This blog emphasizes a comparative analysis between double bottle suction machines and traditional liquid handling systems. Traditional systems often rely on manual processes or outdated pumping methods, which can lead to inconsistencies, inefficiencies, and increased risk of contamination. In contrast, double bottle suction machines streamline the process, offering improved precision and reliability. By utilizing dual vessels, these machines can manage higher volumes of liquid with minimal human intervention, thus enhancing operational efficiency.

The advantages of double bottle suction machines extend beyond mere volume handling. These innovative solutions minimize waste and reduce the risk of cross-contamination, which is critically important in sensitive environments like laboratories. The design of double bottle systems allows for better suction control and ease of use, making them an ideal choice for various applications, from chemical analysis to pharmaceuticals. As more industries recognize the myriad benefits of adopting double bottle suction technology, the traditional systems may soon become a thing of the past, heralding a new era of efficient liquid handling.

Efficient liquid handling is essential in laboratory environments, where precision and speed directly contribute to productivity. The ability to accurately transfer liquids minimizes the risk of errors, ensuring that experimental results are reliable and reproducible. In today’s fast-paced research settings, time is of the essence; any delays in handling procedures can significantly impact project timelines and outcomes. By implementing innovative solutions such as a double bottle suction machine, laboratories can streamline their processes and enhance their overall efficiency.

One of the key benefits of using advanced liquid handling tools is the reduction in manual labor. Traditional methods often involve cumbersome steps that not only slow down operations but also increase the likelihood of contamination. A double bottle suction machine automates many of these tasks, allowing researchers to focus on their core activities rather than the tediousness of liquid transfer. This automation not only leads to greater accuracy but also frees up valuable human resources, enabling laboratory staff to engage in more strategic and creative aspects of their work. In essence, effective liquid handling solutions pave the way for higher throughput and improved research outcomes.

The landscape of liquid handling is evolving rapidly, with ongoing innovations pushing the boundaries of efficiency and reliability. Future trends indicate a significant shift toward automation and smart technologies. These advancements not only streamline processes but also minimize human error, drastically improving the accuracy of liquid transfer. The integration of artificial intelligence and machine learning into liquid handling systems is particularly noteworthy, enabling predictive maintenance and real-time monitoring that enhance operational workflows.

Moreover, market potential for these innovations is substantial. As industries like pharmaceuticals, biotechnology, and food production increasingly demand sophisticated liquid handling solutions, the adoption of advanced technologies will rise. Double bottle suction machines, for instance, are becoming essential tools in laboratories and production lines, driving the need for suppliers to adapt and innovate continuously. Companies that focus on research and development in this sector will likely see considerable growth opportunities, positioning themselves at the forefront of this transformative wave in liquid handling.